Threshing and separation concept of T-Series Combine

Threshing and separation concept of T-Series Combine

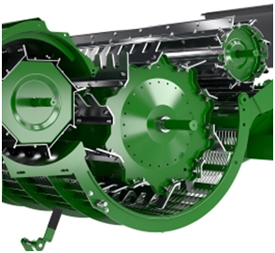

Functional components:

- Large, 660-mm (26-in.) diameter threshing cylinder with 10 rasp bars and increased concave area

- Smooth stripper roll and enlarged overshot beater

- Enlarged, 800-mm (31.5-in.) separator with high-performance separation grate

- Eight-wing, 400-mm (15.7-in.) rear beater and rear beater grate

- Seven-step straw walker design with welded or optional bolted universal and corn-cob mix (CCM) grids

- Sectional concave with quick adjustable de-awning plates

Large, 660-mm (26-in.) threshing cylinder with 10 rasp bars and enlarged concave

The unique multi-drum threshing system ensures a consistent crop flow by moving crop above the rear beater without sharp bends or abrupt changes in direction. This guarantees excellent grain and straw quality and reduces power requirements.

The large, 10-rasp bar threshing cylinder with 660-mm (26-in.) diameter provides excellent grain quality and gentle material handling.

Combined with the enlarged wrapping angle of 124 degrees, this ensures excellent threshing efficiency and unmatched capacity even in tough separating conditions.

- Four rasp bars are in constant contact with the crop against the concave area for excellent threshing and separating

- Provides a large concave area and allows a slow cylinder speed

- Ensures gentle threshing and separation to reduce grain damage

- Large, concave wrapping angle ensures high grain separation right at the beginning and reduces separation load on the straw walkers

- Wide, 1670-mm (65.7-in.) (six-walker) channel width grants maximum throughput even in tough separating conditions

Stripper drum and overshot beater

Stripper drum

Stripper drum

Overshot beater

Overshot beater

The T-Series Combine threshing system uses a smooth surface stripper roller behind the threshing cylinder to gently direct the material to the overshot beater. This prevents material from back feeding on the threshing cylinder, eliminating blockages of the cylinder. The stripper roller speed runs at 125 percent ratio of the threshing cylinder speed.

The 500-mm (19.7-in.) overshot beater on the T-Series Combine continues the material flow process. Material travels over the top of the beater and is directed into the separation drum.

Smooth crop flow is achieved without harsh angles or abrupt changes in direction.

The eight-wing beater has a constant speed. The serrated design of the wings’ leading edges engages the mat of material and moves the high volumes of tough, damp straw without buildup or bunching.

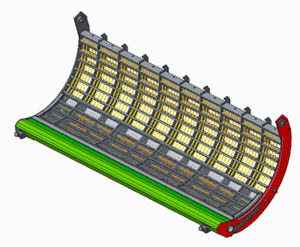

Sectional concave with quick adjustable de-awning plates

Sectional concave with small-grain inserts

Sectional concave with small-grain inserts

Feature benefits:

- High versatility and flexibility with three different concave inserts available

- Uptime ensured with fast exchange design

- Easy access from stone trap and storage position for the concave inserts

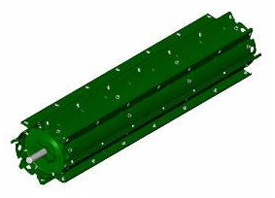

Extra-large separator and dynamic tangential grate

Extra-large separator and dynamic tangential grate

The 800-mm (31.5-in.) extra-large separator drum provides additional separation capacity on the T-Series Combine. Due to the open design, the drum is not heavier in weight than the previous closed design.

The extra-large separator drum runs at two factory-installed speeds:

- 760 rpm for small grain and grass seed

- 380 rpm for canola, peas, and beans

There is an optional 270-rpm speed reduction kit available for corn harvest which is included in the corn package. Swapping the belt speed can be done easily and quickly by changing the drive pulley via a lever-operated tension pulley.

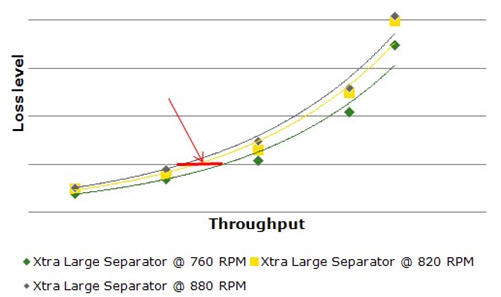

The extra-large separator drum runs at a lower speed compared to the previous T670 design that was operated at 900/450 rpm. While it seems that higher drum speeds result in more efficient separation capacity caused by the higher centrifugal force, the opposite effect has been measured. While the centrifugal force has a vital impact on the separation capacity, speeds of the separator drum that are too high result in low exposure time in the high-performance separator grate. This is shown in the following graph.

Comparison of separator speed

Comparison of separator speed

Comparison of separator speed

The red line indicates the performance delta at a loss level of one percent between the different separator speeds.

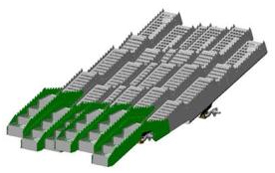

The dynamic tangential grate (new beginning in model year 2019) features a completely updated design equipped with a full wire profile as described below.

Dynamic tangential grate

Dynamic tangential grate

For model year 2019 and newer, the design was changed for fewer restrictions on crop flow and optimal separation that would not affect straw quality.

- All the transversal bars are produced with round edges for better crop flow and straw quality.

- All the wires are repositioned as close to the upper edge as possible to prevent any straw accumulation, therefore improving separation capacity.

- The wires are implemented on the complete area and replace finger rakes for larger opening areas (+10 percent opening area versus model year 2016 tangential grate).

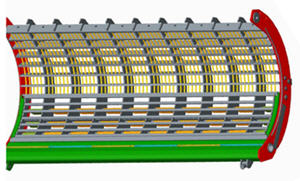

Rear beater and rear beater grate

Rear beater

Rear beater

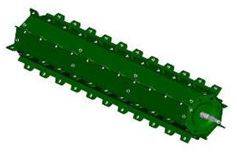

The 400-mm (15.7-in.) rear beater on the T-Series Combine continues the material flow process. The beater delivers material to the straw walkers. The beater is driven directly from the extra-large separator drum and is operated at two speeds.

- 900 rpm for small grain and grass seed

- 450 rpm for rape seed, corn, peas, and beans

A separation grate is mounted underneath the rear beater. The grate is adjustable with a handle on the right side.

The rear separation grate features 14 percent more open area in the separator grid and a fully rounded profile on the wires and cross bars. This creates a better separation effect thanks to a faster, unobstructed crop flow over the grid with a thinner layer of material to boost the separation of kernels trapped in straw.

Two positions are available:

- Wide position recommended in rape seed, corn, peas, beans, or other sensitive crops

- Narrow position for small grain or grass seed

Inside the T-Series threshing and separation system is an eight-winged, rear beater drum that separates the remaining grain out of the straw mat. The rear beater grate provides additional active separation area.

Straw walker concept

Seven-step straw walker design

Seven-step straw walker design

The T-Series Combine has a seven-step straw walker concept. Compared to the previous T-Series, the model year 2017 and newer straw walker is extended by 80 mm (3.15 in.), which results in a slightly increased overall straw walker area (+ 0.1 m² [1.08 sq ft]). The concept of low walker rpm and high walker stroke provides efficient tossing to fluff even largest straw mats and open channels for the free grains to drop through. This results in most efficient grain separation capability. The straw walker is available with welded or bolted universal and CCM grids for best-in-class reconfiguration and ability to retrofit for all crops and conditions.

The straw walker is equipped with a closed walker trough at the rear, which ensures the grain is captured in the trough and feeds evenly on the walker return pan that is mounted below the front section of the walkers. Section dividers on the return pan help to maintain an even distribution of material onto the front chaffer of the cleaning system, even on slopes.

- High throw provides efficient tossing to fluff even the largest straw mats and open channels for the kernels to drop through.

- Maximum grain separation is achieved at the front section due to the impact of the straw mat when hitting the first walker steps.

- Four shallow, angled steps provide maximum separating efficiency.

Different walker grids are available to match all crop and conditions.

Overall threshing and separation system benefits:

- Greater level of productivity due to the enlarged concave wrapping angle, extra-large separator drum, and the high-performance separator grate

- Best-in-class grain and straw quality can be achieved with the threshing and separating concept

- Fast and easy adoption for different crops

- Lower power consumption and excellent straw quality, making this combine the optimal choice for straw producers

Theory of operation

Versatility on a combine is increasingly important as producers must handle multiple crops, sometimes changing between crops during the day.

The threshing needs are very different from crop to crop. Coarse grains like corn or peas require a round bar profile that is less aggressive to ensure optimal grain quality. Small grains including grass seed, vegetables seeds, and durum wheat need intensive threshing and require a small-grain concave profile which provides aggressive threshing to separate the grain.

The sectional concave is made with a fixed concave associated to a removable design on the front where the threshing begins.

Producers can install three different concave profiles:

- Small-grain concave inserts

- Universal concave inserts

- Round-bar concave inserts

- Sectional concave with round-bar concave inserts

Producers can exchange the concave inserts in 15 to 20 minutes by opening the stone trap.

Concave inserts can be exchanged on the combine

Concave inserts can be exchanged on the combine

A screw is available on the left side and maintains the concave inserts in the working position. When the operator loosens the screw, he can easily remove the two inserts and replace them with another set of inserts.

On the right side, the operator has the capability via a screw to install or remove the swing in/out booster bar.

The machine is delivered with small-grain inserts installed and can receive additional universal inserts as factory installed (in storage) or round-bar inserts as dealer installed.